RESTORATION 2005 – 2007

Summer 2005

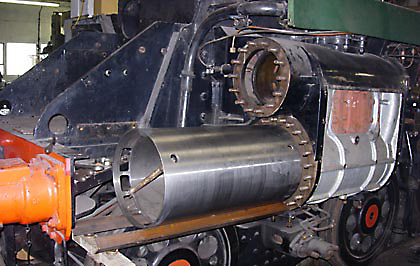

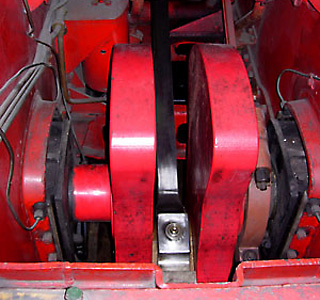

The chassis i.e. wheels, frames etc. of No. 34059 are now in the workshop for further work on the lubrication pipework and the insertion of cylinder liners in the outside cylinders. The middle cylinder does not need attention as this was replaced by a new casting when the class was rebuilt.

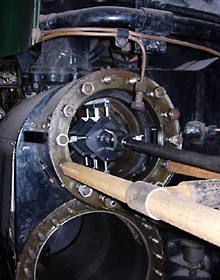

The spun cast iron liners have had the inlet ports machined and were fitted into the cylinders on the 20th June. The liners are 10/1000" undersize to allow insertion into the cylinders. The liners are held in place with Loctite 640 adhesive at £103 for 150ml and will be pegged in place once the adhesive has cured.

|

|

|||

| Machining the inlet ports in the liners. | The left-hand cylinder liner being inserted on 20th June. | |||

November 2005

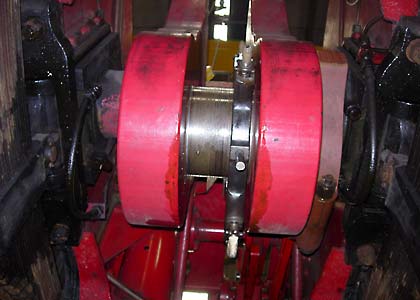

Currently work is centred around the middle cylinder connecting rod. The rod itself is being 'finished' to attain the appropriate radius sections on the edges. More importantly, the fork end of the rod, housing the bearing surface has been re-metalled and scraped in to fit the big end journal.

|

|

|||

| The inside connecting rod being worked on. The newly fitted Monitor injectors can be seen behind. |

The re-metalled centre bearing. | |||

|

|

|

| Machining the middle big end using the Egob – viewed from below. | ||

The big end journal has been 'machined' using the Egob, an ex Eastleigh tool which allows the user to polish the journal surface of the crank axle. Application of engineer's blue to the big end journal surface and then the rotation of the re-metalled centre bearing on the journal enables the fit of the bearing to match that of the big end - after appropriate scraping of the bearing surface if necessary.

Cladding - and insulation - is being fitted to the outside cylinders - yet another job to be ticked off.

December 2005

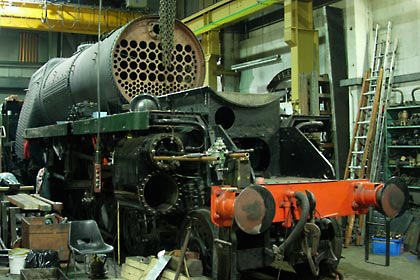

The boiler of No. 34059 has been temporarily placed on the frames to make room for No. 75027 to enter the workshop for maintenance.

|

|

|||

| The boiler temporarily placed on the frames with the honing machine in position. | Honing of the valve chest liner on the right hand side. | |||

|

|

|

||||

| Machining of the casting of the brake ejector is almost complete and trial fitting of the components is underway. | Work has started on re-cladding cab frame. | |||||

March 2006

Now that space is available in the workshop the boiler and cab have now been taken off the chassis to enable work to be carried out easily.

|

|

|||

| he boiler has been positioned at the back of the workshop. The chassis can be seen behind, with the cab behind that. | The middle connecting rod was fitted on Tuesday 21st February. This view (taken from below) shows the crosshead and union link. | |||

|

|

|||

| The crank axle (taken from above) with the eccentric strap on the right. | This picture is interesting as it clearly shows the original safety valve holes in front of the dome, which have been blanked-off. | |||

April 2006

The boiler of No. 34059 is now being actively worked on by the workshop staff. The new firebox tubeplate has been tack welded in position and awaits an inspection prior to final welding by a coded welder.

|

|

|||

| Further work is being undertaken on the new sections of the foundation ring prior to their machining and eventual welding. | The section of the throatplate that has ben removed is being prepared for the insertion and welding in place of the new plate formed by Roger Pridham. | |||

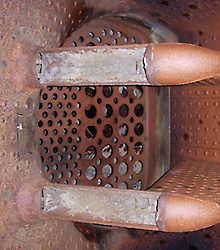

Stud holes for the boiler top fittings are being cleaned and re-tapped. The large and small tube holes in the front tube plate are being cleaned and prepared for eventual tube fitting, a task that will also have to be undertaken on the new firebox tube plate.

On the locomotive chassis, work is proceeding on the running plates where paint work has suffered.

May 2006

Now that space is available in the workshop the boiler and cab have now been taken off the chassis to enable work to be carried out easily.

|

|

|||

| The boiler of No. 34059 has been turned to facilitate work on the firebox. | New firebox tubeplate and throat plate section in place. | |||

|

|

|||

| The cab roof being re-clad. | The right side window frame in place. | |||

November 2006

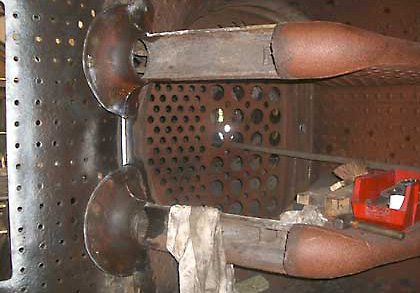

The bottom section of the firebox has been cut out and new sheeting is being cut to be welded into place. The twenty six flexible stays and cups which surround the syphon plugs have been removed and will be replaced with new ones, owing to the amount of corrosion.

|

|

|||

| The re-clad cab has now been painted. | Flexible stays removed from around the thermic syphons. | |||

January 2007

Pipework for the injectors has been delivered and is being fitted to the injectors and connected to the pipe runs along the footplating. Work is progressing on the overhaul of the AWS equipment, most of which is now to hand. Work on the cab is almost complete and much preparation and painting has been undertaken of the cab and the new sheeting. The ashpans are being overhauled and painted where necessary.

|

|

|||

| Injector pipework being worked on. | Syphon sections | |||

We are forming the new sections for the syphons on site using the preformed U sections manufactured by Pridhams

April 2007

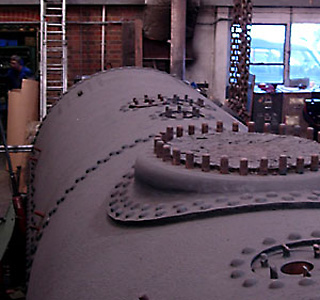

The boiler has now been inverted with the base of the firebox now uppermost to allow more welding on the syphon patches and the diaphragms and for additional sections of the rear inner firebox plate adjacent to the foundation ring to be cut out for new plate. All the lower sections of the firebox will then have been removed for replacement with new plate.

|

|

|||

| The inverted boiler. | The welding work carried out on the syphons. | |||

May 2007

Is this the beginning of the end? The nameplate holders have been cut out and the nameplate and plaque have been trial fitted.

|

|

|||

| Nameplate trial fitted. | Together again but the meeting may well be brief. | |||

The tender is in the works as space outside is tight and it will enable some rubbing down of the paintwork and repainting of some areas.

No. 34059's overhaul progresses with further firebox repairs taking place. The new plate on the lower section of the firebox on the fireman's side has ben tack welded in position and now awaits welding and then the drilling and tapping of the stay holes. There has been trial fitting of the new corner sections of the foundation channel.

|

|

|||

| The inner firebox plate below the firehole door has been cut out and the stays removed. | The new plate on the fireman's side and the corner sections of the foundation channel trial fitted. | |||

Work is progressing on the injection to clack valve pipework, with only one major section awaiting completion.

July 2007

Firebox repairs are now concentrating on the bottom corners. The new corner sections are being cut-out from sheet boiler steel and shaped in the hydraulic press.

|

|

|||

| The new smokebox with platework for the steam pipes being trial fitted. | The fettled new foundation ring corner sections. | |||

November 2007

The smoke deflector have been made from new steel sheets, however the handrail stanchions come from the existing ones.

|

|

|||

| The left-hand side having the beading attached. | The lighting conduits being fitted to the smokebox. | |||

|

|

|||

| Firebox stays being fitted. The numbers around the firebox, in yellow, are the diameter of the stay size required for the stay hole. | The welding of the firebox flexible stays has been completed. | |||